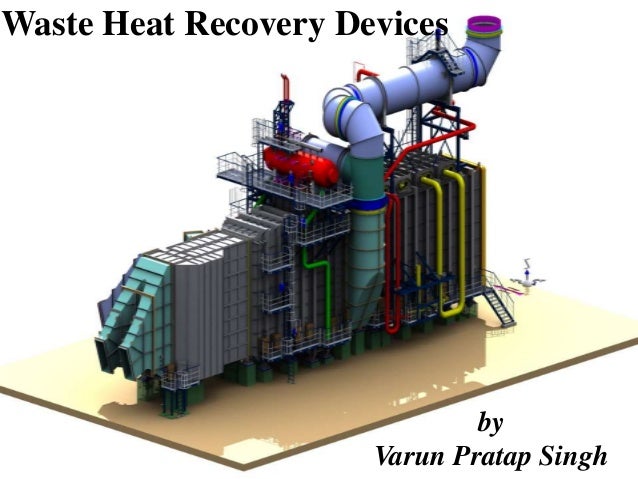

An example of this technique of waste heat recovery would be where the high temperature stage was used for air pre-heating and the low temperature stage used for process feed water heating. Waste heat recovery is to try to recover maximum amounts of heat in the plant and to reuse it as much as possible instead of just releasing it into the air or a nearby river.

Conventional Waste Heat Recovery System With Lpe Download Scientific Diagram

Conventional Waste Heat Recovery System With Lpe Download Scientific Diagram

Complete Closed Loop Systems.

Waste heat recovery system. Waste heat recovery systems WHR are put in each category of loss in order to obtain an optimal recovery efficiency. Combustion Air Pre-Heat System. Although not technically an engine component or function waste heat recovery systems attempt to regain some of the 50 or so lost thermal efficiency from the fuel used in the engine.

The Megaflo SHRU shower heat recovery unit range transfers heat from discharged waste shower water in to the incoming water supply placing less energy load on the boiler to raise. In the simplest terms a system or technology that uses the residual heat from the waste shower water to preheat the incoming cold feed that refills the system. Echogen converts wasted heat into higher value power.

Captured and reused waste heat is an emissionfree substitute for costly purchased fuels or electricity. A closed loop system is an efficient way of capturing wasted energy and transferring it to. Over the years the popularity of using the waste heat recovery systems has grown a lot.

Major shipping players like Maersk MSC etc have WHR systems in most of their vessels. Figure 12 Energy flow without waste heat recovery Figure 13 Energy flow with waste heat recovery Fuel Heat generation boilers heaters Process Cooling Surroundings. This technology can be applied to all ships regardless of size age and type even though.

Waste Heat Recovery Systems Reformed Gas Waste Heat Boiler. Therefore less energy is used to. Learn about our waste heat recovery solution that creates economic clean reliable energy.

Heat recovery feasibility is a financial decision. Waste Water Heat Recovery. The process gas waste heat recovery systems can be used for gas pressure values of up to 350 bar 35000 kPa incoming gas temperatures of up to 1500 C and steam pressure values of up to 160 bar 16000 kPa.

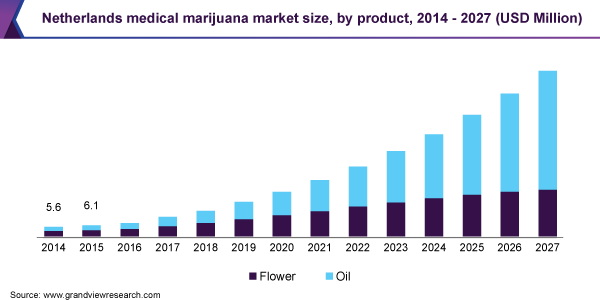

Sigma Thermal engineers are heat energy management experts. The following figure gives an overview of the heat losses in different industrial sectors and their recycling into electrical energy 3. Waste heat sources are matched with potential users and the appropriate heat transfer and control system is designed.

A system normally takes the form of a long vertical copper pipe. The installation cost for this measure is estimated at 5000000 to 9500000 USD per ship. Waste heat recovery systems Waste heat recovery methods include capturing and transferring the waste heat from a process with a gas or liquid back to the system as an extra energy source.

With pressure increasing on shipping sector for reducing the carbon footprints these systems. In some cases such as industrial furnaces efficiency improvements resulting from waste heat recovery can improve energy efficiency by 10 to as much as 50. Waste heat recovery systems are more sophisticated than the simple exhaust gas boiler or economizer and the heat can be used in variety of ways.

Waste Heat Recovery Heat Energy Recovery Audits. Typically a waste water heat recovery system works by extracting the heat from the water your shower or bath sends down the drain. Waste heat recovery systems Applicability and assumptions.

In addition to constantly. WWHRS is the abbreviation of Waste Water Heat Recovery System. However determining the feasibility of a heat recovery system is difficult.

This heat is used to warm the incoming mains water reducing the strain on your boiler and the energy required to heat your water up to temperature. The energy source can be used to create additional heat or to generate electrical and mechanical power. Temperature heat recovery a cascade system of waste heat recovery may be practiced to ensure that the maximum amount of heat is recovered at the highest potential.